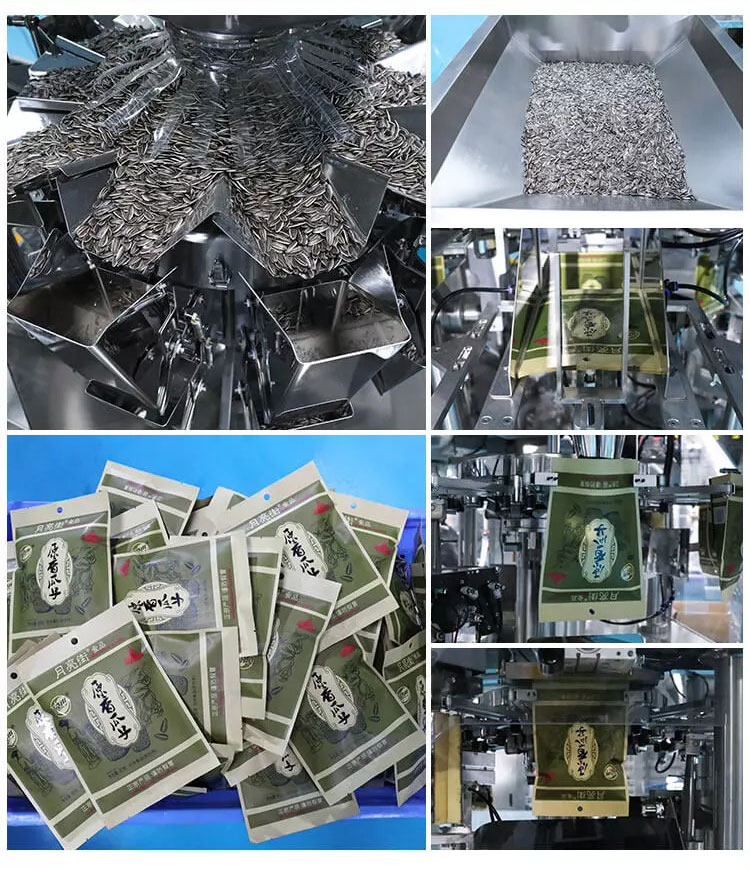

Suitable for small packages (10-2000g) of bulk objects that require high measurement accuracy and fragile, such as: puffed food, crispy rice, jelly, candy, pistachio, crispy fruit and vegetable, grains, hardware, medicinal materials, etc.

DetailsParameterVideoApplication

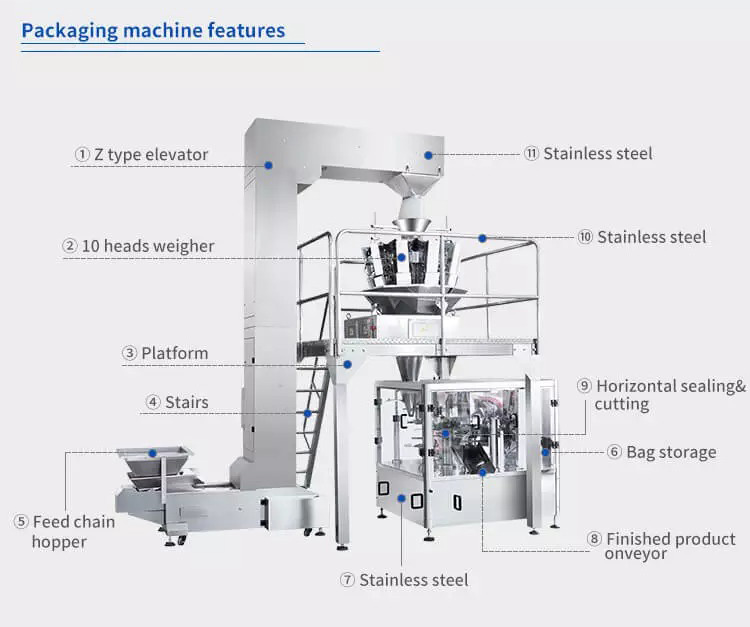

- The equipment is equipped with safety protection, which meets the requirements of enterprise safety management. All contact materials are 304 stainless steel or ABS food grade plastic;

- The equipment can automatically complete the entire packaging process of feeding, metering, filling and bag making, date printing, gas filling (exhaust), and finished

- Product delivery, also automatically completes counting, with high measurement accuracy and high efficiency;

- The equipment is fully controlled by PLC, man-machine interface, and touch screen operation is simple and intuitive;

- The packaging machine is equipped with a detection device, which can detect that the filling device does not fill and the heat sealing device does not seal when there

- Is no packaging or the packaging bag is not opened, so as to avoid wasting packaging materials and raw materials;

- The size of the packaging bag can be changed quickly, and the width of the automatic bag feeding device can be easily and quickly adjusted by adjusting the handle;

- Adopt prefabricated bag packaging, exquisite packaging, level up;

- The packaging bag has a wide range of applications. It can be applied to self-supporting bags made of multilayer composite film, eight-sided bags, paper bags, threesided sealed bags, and zipper bags;

| Type | VK-8-200B | VK-8-250B |

| Packing speed | 20-55bag/min depend on product | 10-45bag/min depend on product |

| Bag size | (L)150-320mm (W)100-200mm | (L)150-320mm (W)100-200mm |

| Bag type | Stand up bag, three-side sealing bag, and other composite bags | |

| Film thickness | 0.04-0.09mm | |

| Air consumption | 0.8Mps 0.5m³/min | |

| Voltage | 380V、50Hz | |

| Machine size(L×W×H) | 1700×1300×1400mm | 1900×1450×1500mm |